Redentore Utopia - Limited Edition

We had a dream from the very first day in our journey: to create a watch belonging to our identity, by designing our own movement, made in Italy, and a timepiece that would be its most coherent expression. It seemed like a utopia, before we met Fausto Berizzi, a historic figure in Italian watchmaking. Together, we brought the V5000 to life: our first caliber designed and built in Italy. Today, that dream takes shape in the Redentore Utopia. It’s a milestone — but for us, it’s only the beginning

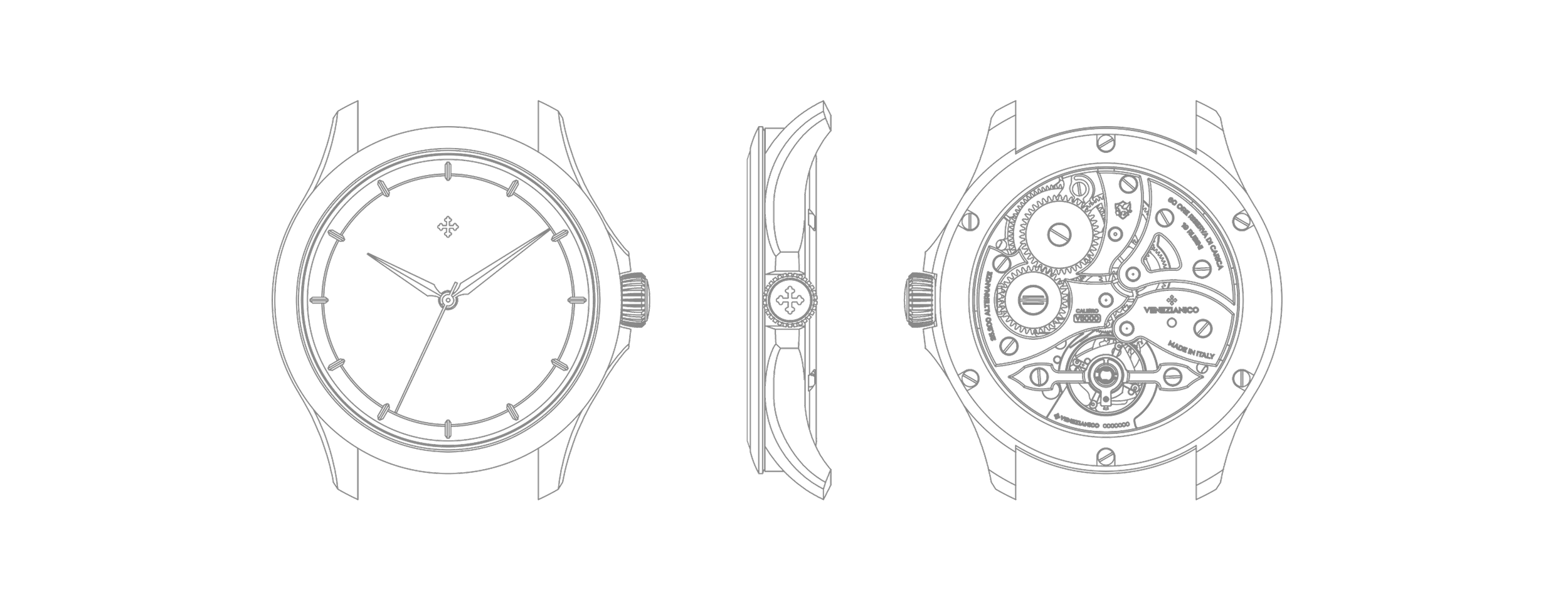

CASE MATERIAL: 316L Stainless Steel

DIAL: Guilloché, hand-engraved on an 1850 rose engine by master Riccardo Renzetti

DIMENSIONS: Ø38 mm, 44.2 mm lug to lug, 8.9 mm thickness

MOVEMENT: V5000, Made in Italy (manufactured by OISA, designed by Fausto Berizzi & Andrea Menegazzo)

CRYSTAL: Sapphire with anti-reflective coating

BEZEL: Polished Stainless Steel

CASEBACK: Exhibition caseback with sapphire crystal, secured with 6 screws

STRAP: Handcrafted embossed leather by Gian Pietro Failli

BUCKLE: 316L Stainless Steel, polished and brushed, engraved

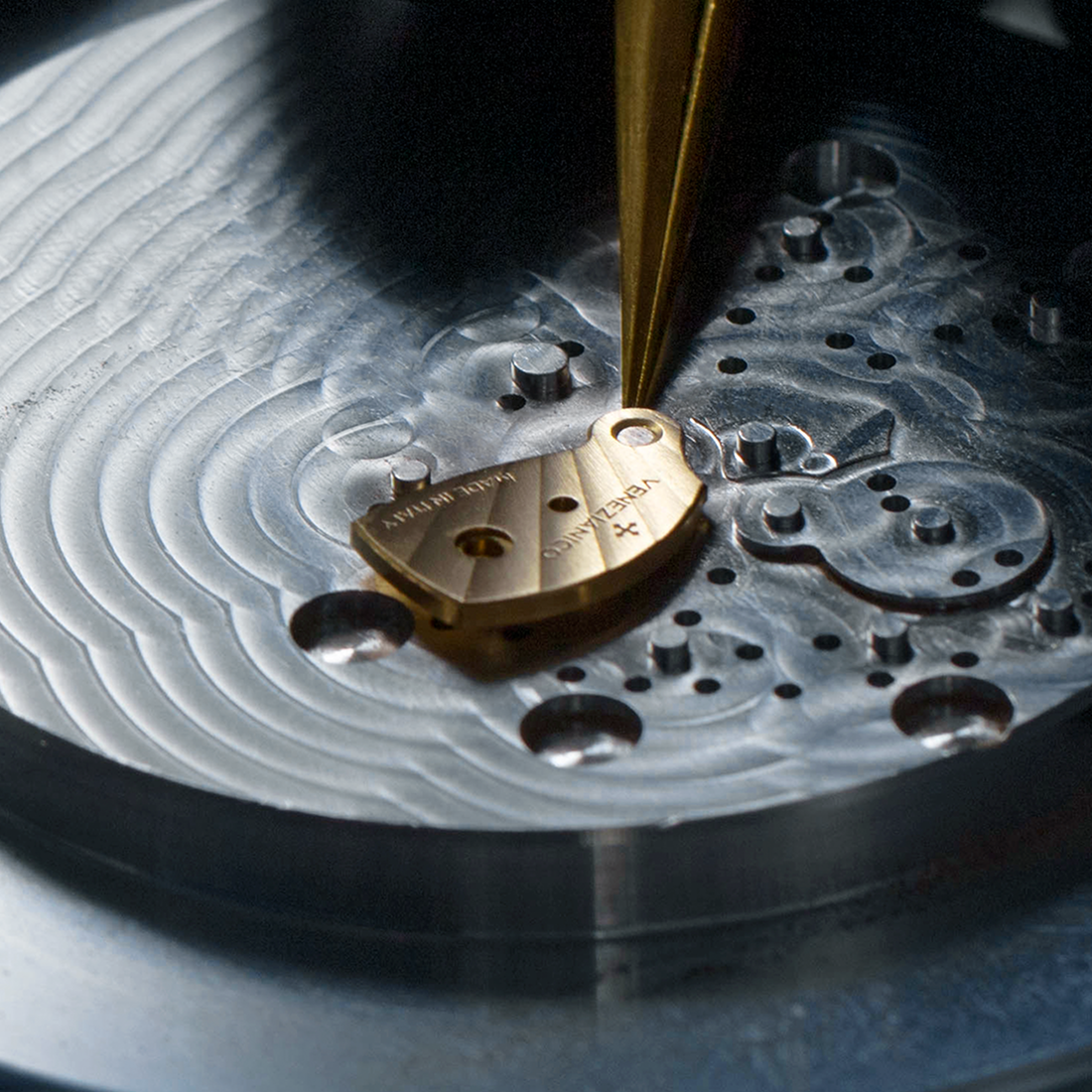

Each timepiece equipped with the V5000 caliber is personally assembled in our Atelier in Italy by Daniele Zorzetto, a master watchmaker with extensive experience in regulating free-sprung balances with masselottes.

All orders include free shipping. Here are the average delivery times:

- EU Countries: 1-2 business days

- United Kingdom: 2-3 business days

- USA: 2-3 business days

- Other Countries: 2-5 business days

If the watch does not meet expectations, it can be returned within 14 days for a full refund of the purchase amount. For more info, check out our Terms and Conditions.

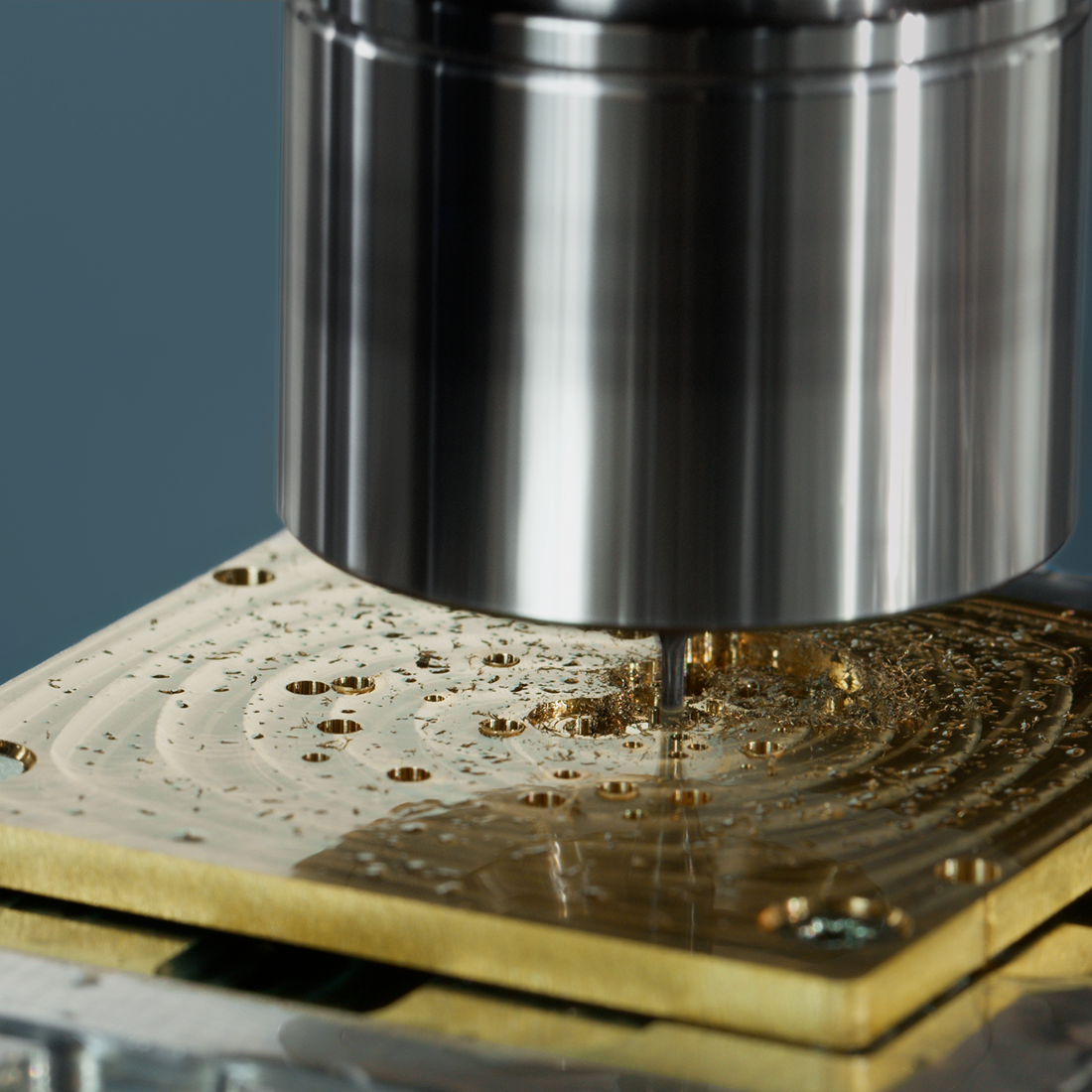

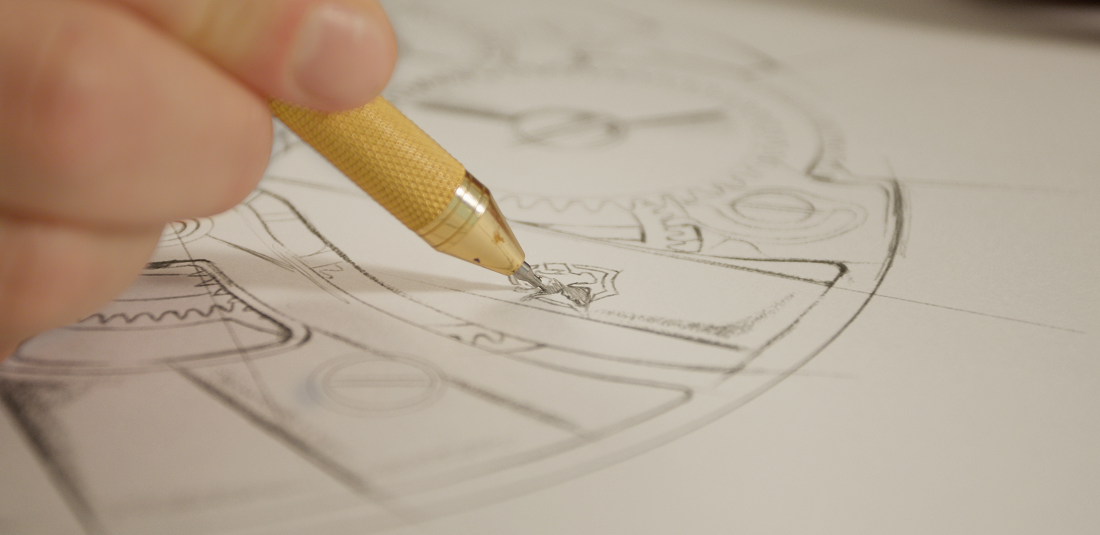

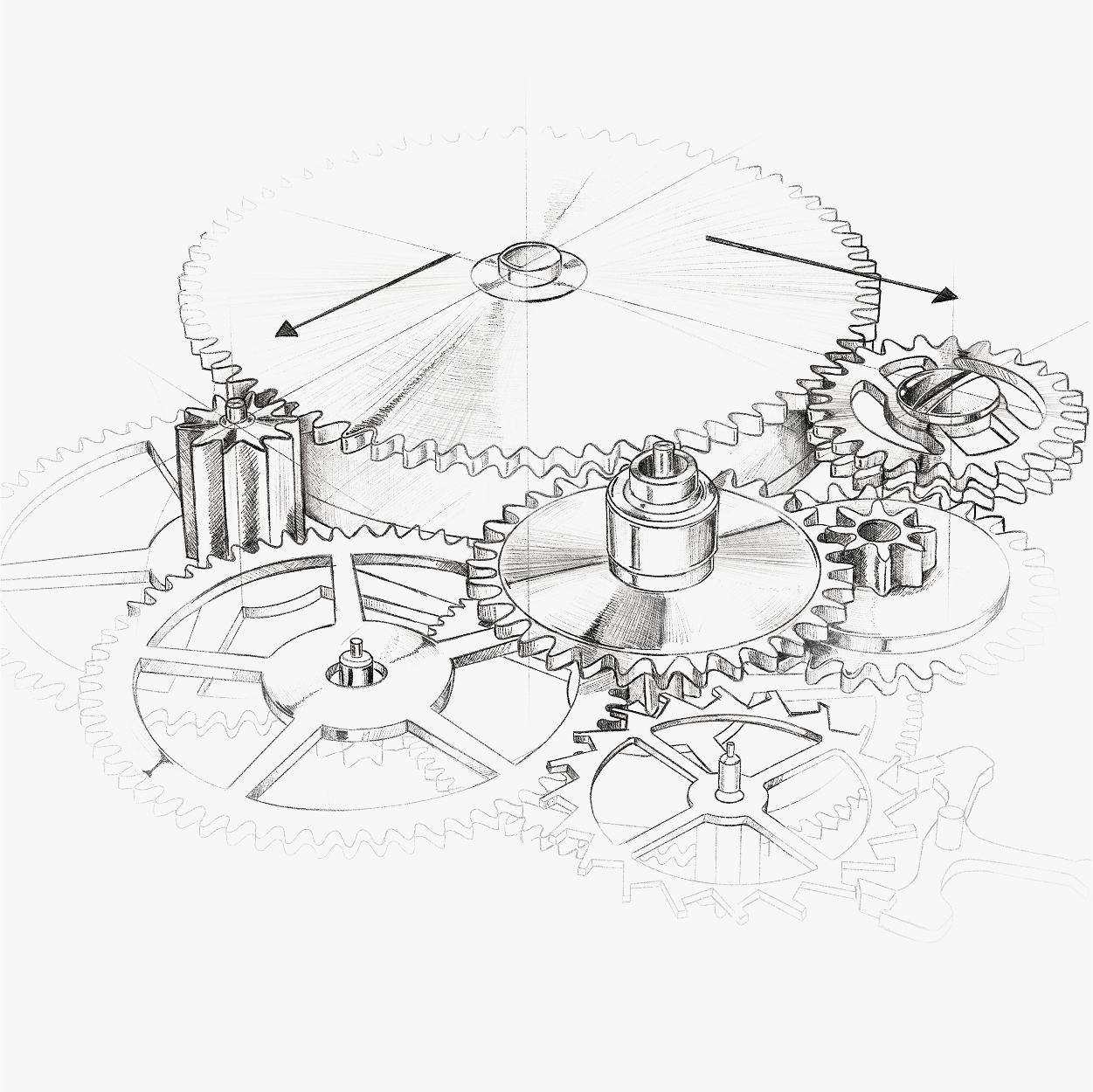

The V5000 was born from the dialogue between Alberto and Alessandro Morelli and our community. Years of discussions shaped a clear vision of what the ideal movement meant to us. Andrea Menegazzo, head of product development, carefully shaped the design with a clear vision and sense of harmony, staying true to our aesthetic. Fausto Berizzi, a key figure in Italian-Swiss watchmaking, brought that vision to life through his expertise in micromechanical engineering. The result is a movement that fully embodies our vision.

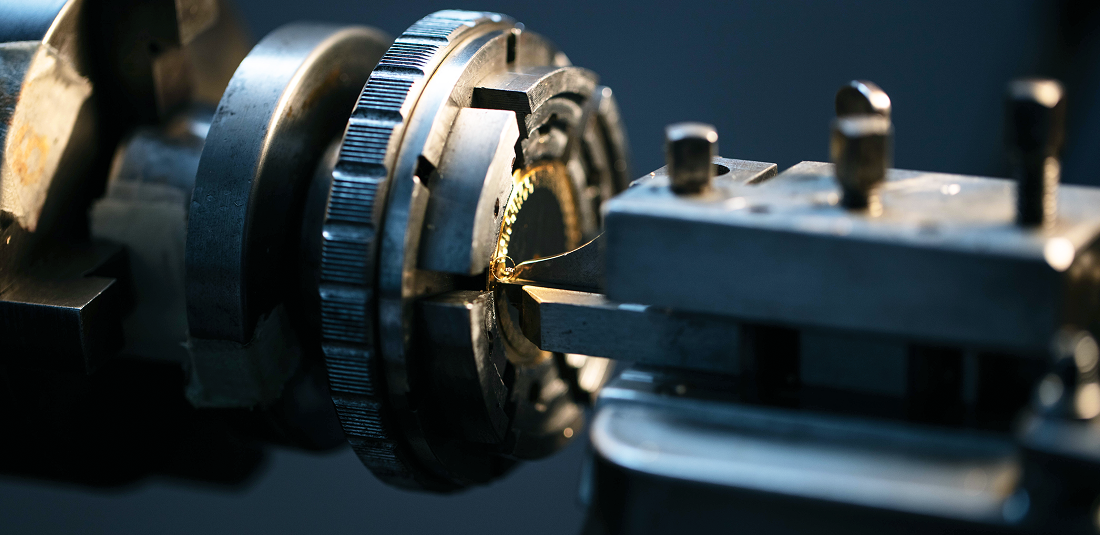

The first watch powered by our manufacture caliber marks a natural evolution in our journey. We brought together rare Italian craftsmanship into a project that’s coherent in every detail—from the mechanical heart to the surface that tells its story. The guilloché dial is hand-engraved by master artisan Riccardo Renzetti using a centuries-old technique, preserved by a handful of craftspeople and antique rose engine lathes. No automation—only slow, precise gestures. The result is a living, unique pattern that mirrors the same care devoted to the movement itself.

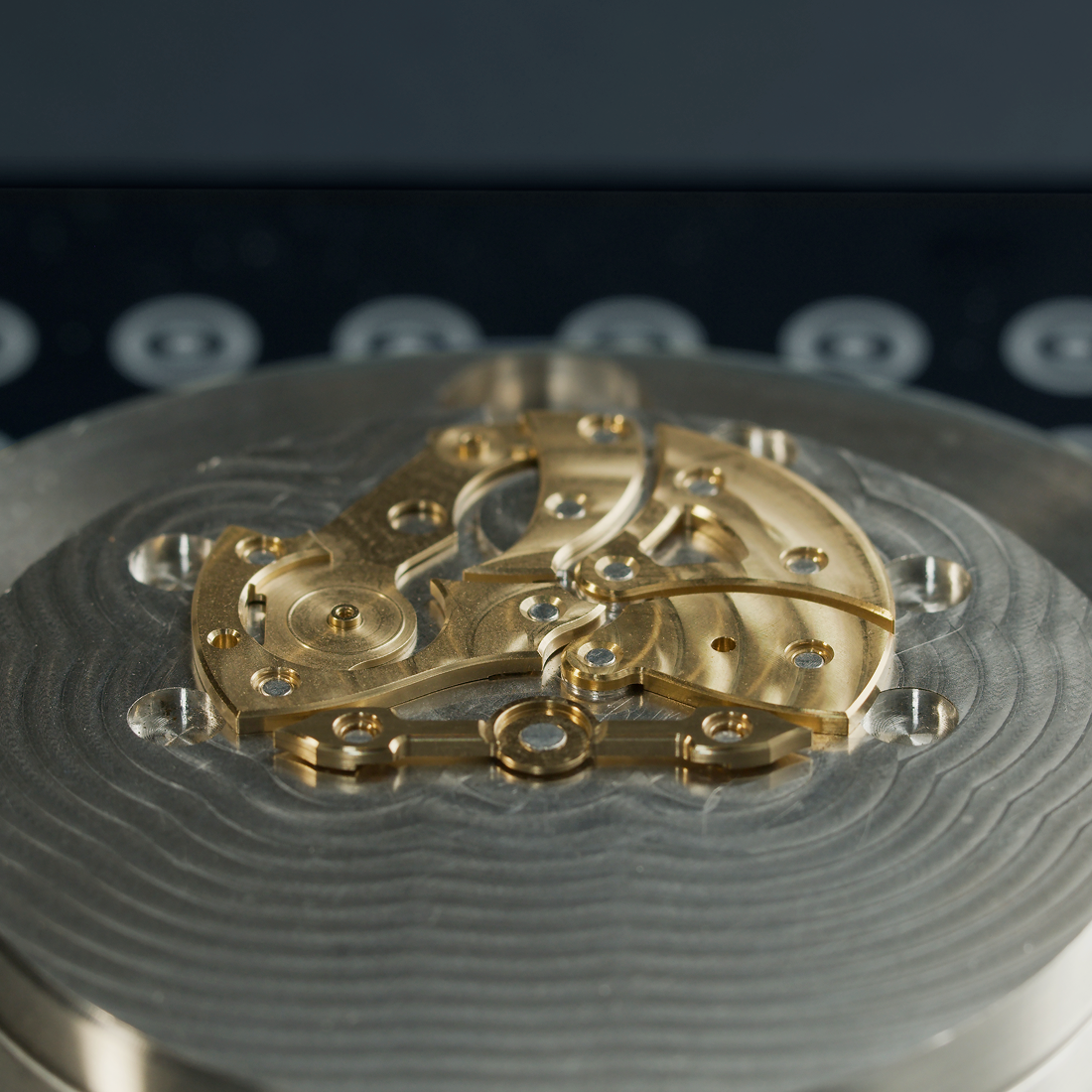

Every aspect of this project has been handled with artisanal precision, combining specialized expertise and traditional techniques. The movement features hand-executed finishes such as microperlage, polished anglage, and radial Côtes de Genève—clear signs of our commitment to detail. This same approach extends to the watch itself: from the hand-crafted embossed leather strap by Gian Pietro Failli to the case, finished with absolute precision. A cohesive creation where nothing is left to chance.

The V5000 was born from the dialogue between Alberto and Alessandro Morelli and our community. Years of discussions shaped a clear vision of what the ideal movement meant to us. Andrea Menegazzo, head of product development, carefully shaped the design with a clear vision and sense of harmony, staying true to our aesthetic. Fausto Berizzi, a key figure in Italian-Swiss watchmaking, brought that vision to life through his expertise in micromechanical engineering. The result is a movement that fully embodies our vision.

The first watch powered by our manufacture caliber marks a natural evolution in our journey. We brought together rare Italian craftsmanship into a project that’s coherent in every detail—from the mechanical heart to the surface that tells its story. The guilloché dial is hand-engraved by master artisan Riccardo Renzetti using a centuries-old technique, preserved by a handful of craftspeople and antique rose engine lathes. No automation—only slow, precise gestures. The result is a living, unique pattern that mirrors the same care devoted to the movement itself.

Every aspect of this project has been handled with artisanal precision, combining specialized expertise and traditional techniques. The movement features hand-executed finishes such as microperlage, polished anglage, and radial Côtes de Genève—clear signs of our commitment to detail. This same approach extends to the watch itself: from the hand-crafted embossed leather strap by Gian Pietro Failli to the case, finished with absolute precision. A cohesive creation where nothing is left to chance.

Cal. V5000

The V5000 is our first proprietary mechanical movement, designed and manufactured in Italy. It offers a 60-hour power reserve within a remarkably slim 3.5 mm profile, and an accuracy of ±3 seconds per day. It features a variable-inertia balance wheel made of copper-beryllium with four masselottes, a dual-anchored balance bridge, KIF Elastor shock protection system, and anti-loosening screws. Every detail is finished by hand with artisanal care, including radial Côtes de Genève, polished anglage, and micro-perlage.

25,200 vibrations/hour (3.5 Hz)

60 hours

Free-sprung with 4 masselottes, made of copper-beryllium by Atokalpa

±3 seconds per day

3.5mm

Radial Côtes de Genève, mirror-polished anglage, hand-applied micro-perlage

Bridges machined from solid and treated with chemical nickel

Made in Italy from proprietary design (n. 402025000000420), manufactured by OISA

The Seal of Quality

Engraved on every V5000 caliber, this symbol represents the quality standard that defines our movement. It certifies that the caliber is designed and manufactured in Italy, following strict criteria that include:

– hand-executed artisanal finishing

– average accuracy of ±3 seconds per day

– registered proprietary design (Design and Model No. 402025000000420)

– extended 5-year warranty

The Expertise of Berizzi, Technical Director at OISA

Crafted by Atokalpa from a copper-beryllium alloy, this balance wheel is regulated using four masselottes — small peripheral weights that allow the inertia to be adjusted without changing the active length of the hairspring. Compared to traditional balance wheels with a regulator index, the variable inertia system enables more precise and stable regulation over time, minimizing the impact of shocks or positional changes on the watch’s accuracy. This type of balance wheel is typical of haute horlogerie, where long-term chronometric performance is a top priority.

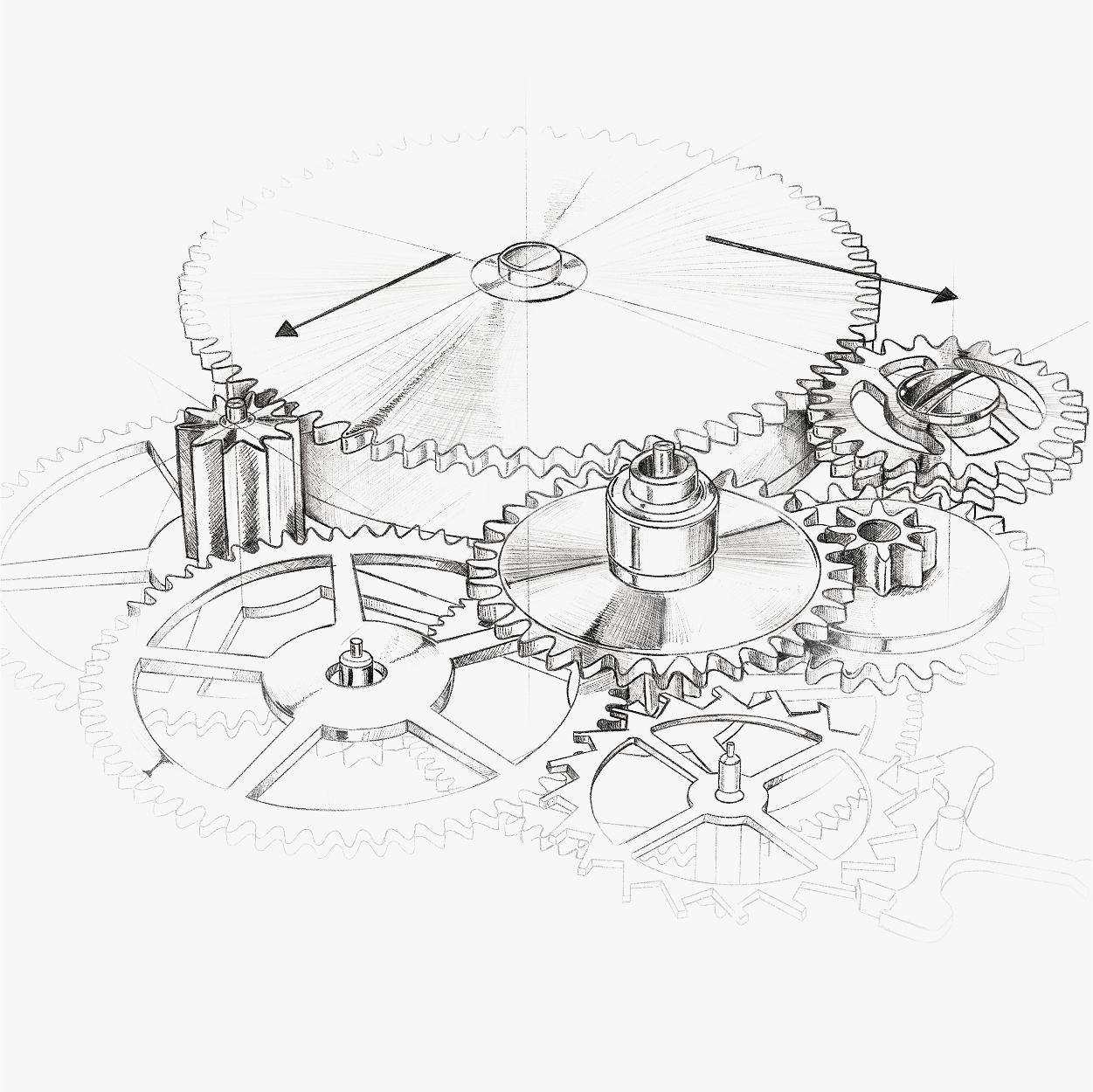

In this system, the transmission of motion is divided into two separate branches: one dedicated to the seconds, the other to hours and minutes. This mechanical separation reduces interference between the gear trains, preventing the continuous motion of the seconds hand from affecting the consistency of the main timekeeping system. The result is greater running stability and more reliable long-term accuracy. A refined approach to movement construction, designed with precision as its highest priority.

Carefully engineered to balance efficiency and practicality, the V5000 is featured by a 60-hours power reserve — well above the average for mechanical movements. This relevant interval allows the watch to maintain stable and accurate timekeeping even after several days of rest, eliminating the need for unnecessary adjustments or winding. It’s a power reserve designed to naturally adapt to different wearing habits, whether used daily or rotated with other timepieces, always ensuring readiness and consistent performance.

KIF Parechoc is a Swiss company specializing in shock protection systems for mechanical movements. In V5000 caliber, we use the KIF Elastor, designed to safeguard the balance against sudden impacts. A star-shaped helical spring, placed around the jewel setting, absorbs the shock’s energy and get back the balance wheel to its optimal position. This compact system offers greater precision and stability compared to simpler alternatives, enhancing the movement’s durability even under dynamic conditions.

Crafted by Atokalpa from a copper-beryllium alloy, this balance wheel is regulated using four masselottes — small peripheral weights that allow the inertia to be adjusted without changing the active length of the hairspring. Compared to traditional balance wheels with a regulator index, the variable inertia system enables more precise and stable regulation over time, minimizing the impact of shocks or positional changes on the watch’s accuracy. This type of balance wheel is typical of haute horlogerie, where long-term chronometric performance is a top priority.

In this system, the transmission of motion is divided into two separate branches: one dedicated to the seconds, the other to hours and minutes. This mechanical separation reduces interference between the gear trains, preventing the continuous motion of the seconds hand from affecting the consistency of the main timekeeping system. The result is greater running stability and more reliable long-term accuracy. A refined approach to movement construction, designed with precision as its highest priority.

Carefully engineered to balance efficiency and practicality, the V5000 is featured by a 60-hours power reserve — well above the average for mechanical movements. This relevant interval allows the watch to maintain stable and accurate timekeeping even after several days of rest, eliminating the need for unnecessary adjustments or winding. It’s a power reserve designed to naturally adapt to different wearing habits, whether used daily or rotated with other timepieces, always ensuring readiness and consistent performance.

KIF Parechoc is a Swiss company specializing in shock protection systems for mechanical movements. In V5000 caliber, we use the KIF Elastor, designed to safeguard the balance against sudden impacts. A star-shaped helical spring, placed around the jewel setting, absorbs the shock’s energy and get back the balance wheel to its optimal position. This compact system offers greater precision and stability compared to simpler alternatives, enhancing the movement’s durability even under dynamic conditions.

The dial is hand-engraved using the guilloché technique on a rose engine lathe, following an exclusive design created for this model. The radial pattern emerges from slow, mechanical gestures, guided by the artisan's eye. To enhance its vibrancy, the metal is treated with an IP coating, giving it a deep, changing tone. Reflections move along the engraving, creating a dynamic effect that highlights every detail of the craftsmanship

In a dial rich in details like guilloché, every element must find its place with balance. That's why we've chosen alpha hands, faceted and polished to a mirror finish, which reflect the light and ensure readability. The indices, in stick form, are hand-applied with precision, following the curve of the dial without disrupting its rhythm. Every detail contributes to creating a sober and measured aesthetic, perfectly in line with the essential philosophy of the Redentore Utopia.

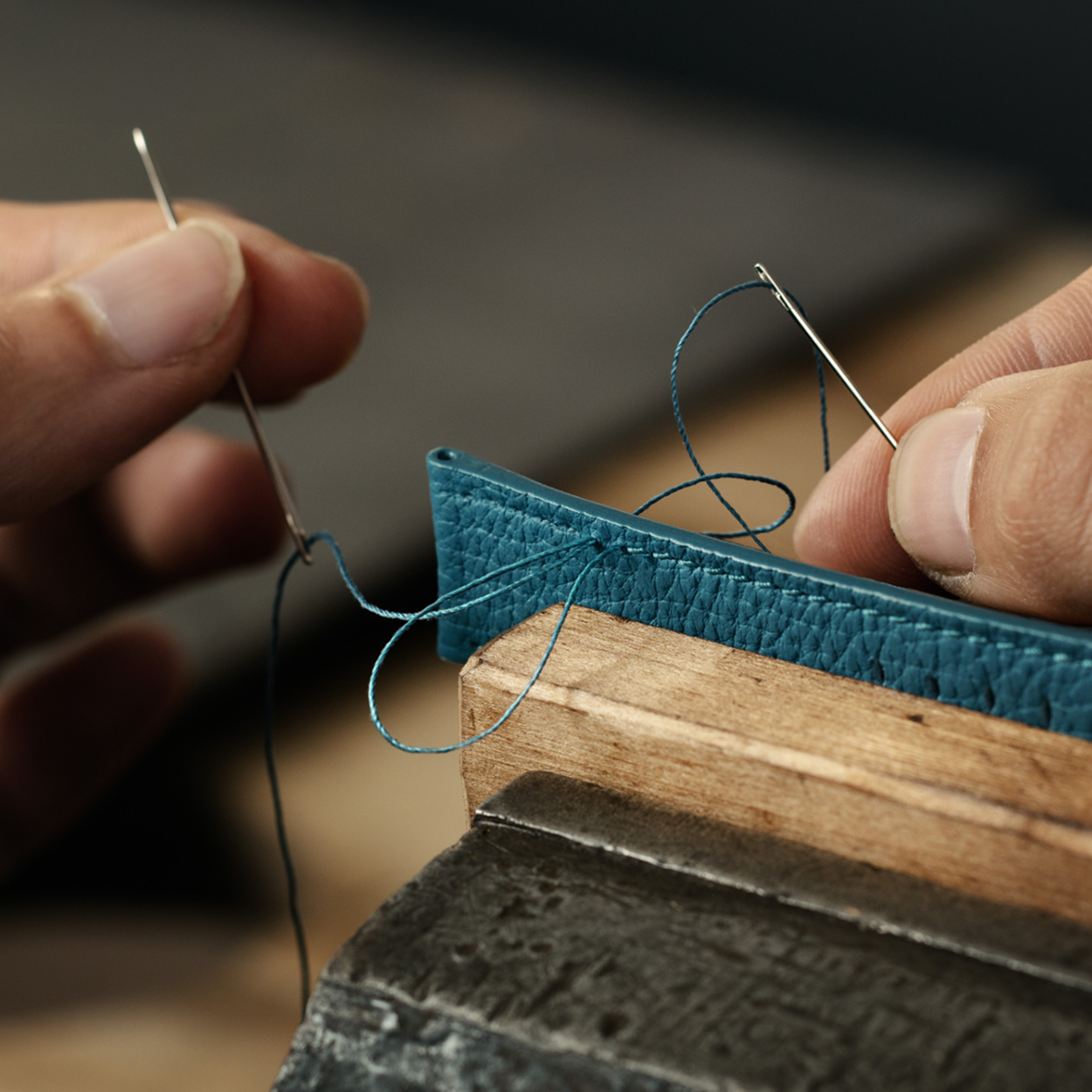

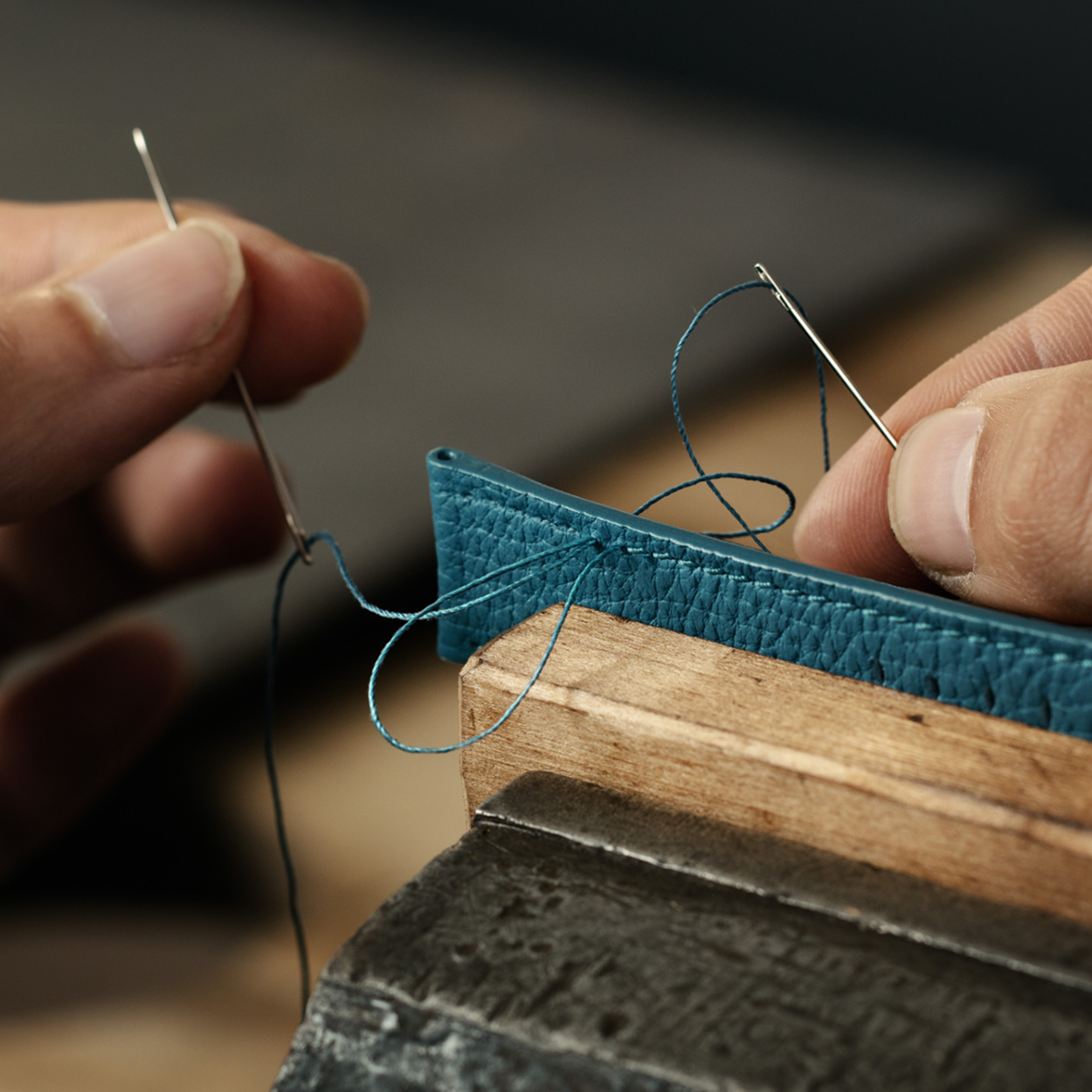

Handcrafted by Gian Pietro Failli in his Tuscan workshop, the strap of the Redentore Utopia is born from a genuine leatherworking tradition. Every step is carried out with artisanal precision and aesthetic sensitivity: from the measured gestures to the careful selection of materials. The embossed leather, soft and enveloping, is worked using traditional techniques that enhance its texture and durability. A subtle yet essential detail that strengthens the stylistic identity of the timepiece.

The dial is hand-engraved using the guilloché technique on a rose engine lathe, following an exclusive design created for this model. The radial pattern emerges from slow, mechanical gestures, guided by the artisan's eye. To enhance its vibrancy, the metal is treated with an IP coating, giving it a deep, changing tone. Reflections move along the engraving, creating a dynamic effect that highlights every detail of the craftsmanship

In a dial rich in details like guilloché, every element must find its place with balance. That's why we've chosen alpha hands, faceted and polished to a mirror finish, which reflect the light and ensure readability. The indices, in stick form, are hand-applied with precision, following the curve of the dial without disrupting its rhythm. Every detail contributes to creating a sober and measured aesthetic, perfectly in line with the essential philosophy of the Redentore Utopia.

Handcrafted by Gian Pietro Failli in his Tuscan workshop, the strap of the Redentore Utopia is born from a genuine leatherworking tradition. Every step is carried out with artisanal precision and aesthetic sensitivity: from the measured gestures to the careful selection of materials. The embossed leather, soft and enveloping, is worked using traditional techniques that enhance its texture and durability. A subtle yet essential detail that strengthens the stylistic identity of the timepiece.

Ø38 mm, 44.2 mm lug to lug, 8.9 mm thickness

316L Stainless Steel

Guilloché, hand-engraved on an 1850 rose engine by master Riccardo Renzetti

Sapphire with anti-reflective coating

Exhibition caseback with sapphire crystal, secured with 6 screws

Handcrafted embossed leather by Gian Pietro Failli