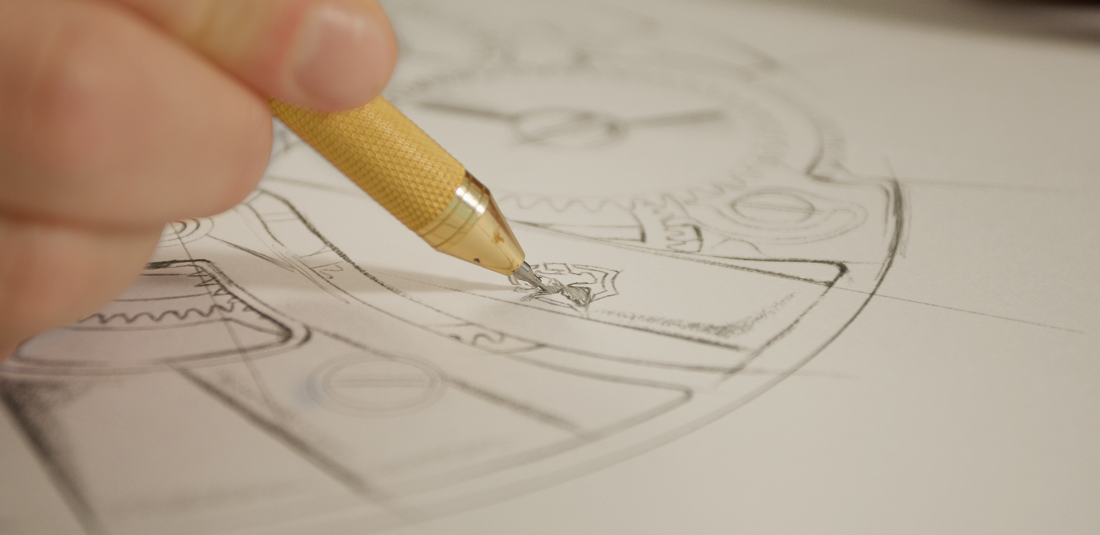

«We had a dream from the very first day in our journey: to create a watch belonging to our identity, by designing our own movement, made in Italy, and a timepiece that would be its most coherent expression. It seemed like a utopia, before we met Fausto Berizzi, a historic figure in Italian watchmaking. Together, we brought the V5000 to life: our first caliber designed and built in Italy. Today, that dream takes shape in the Redentore Utopia. It’s a milestone — but for us, it’s only the beginning.»

Cal. V5000

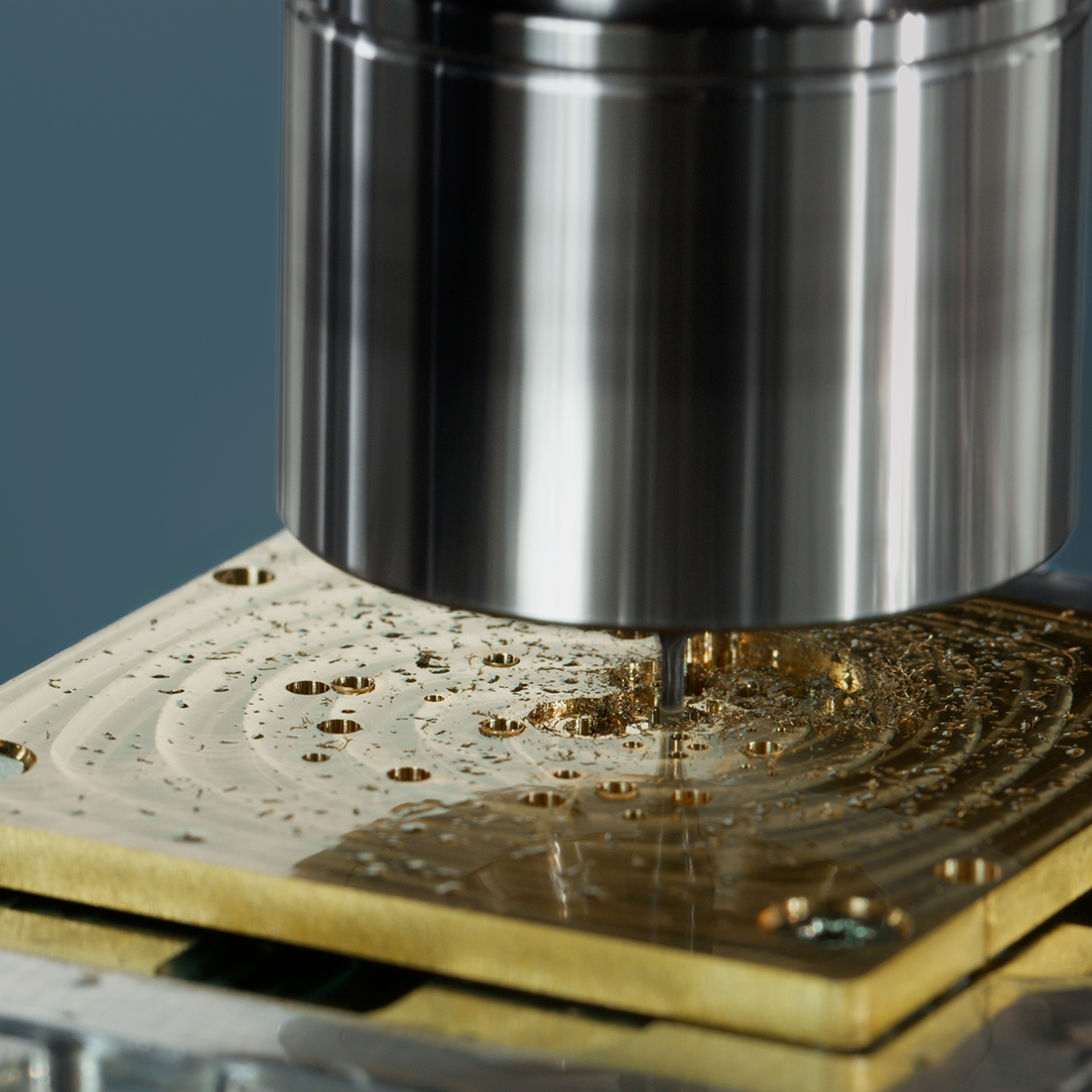

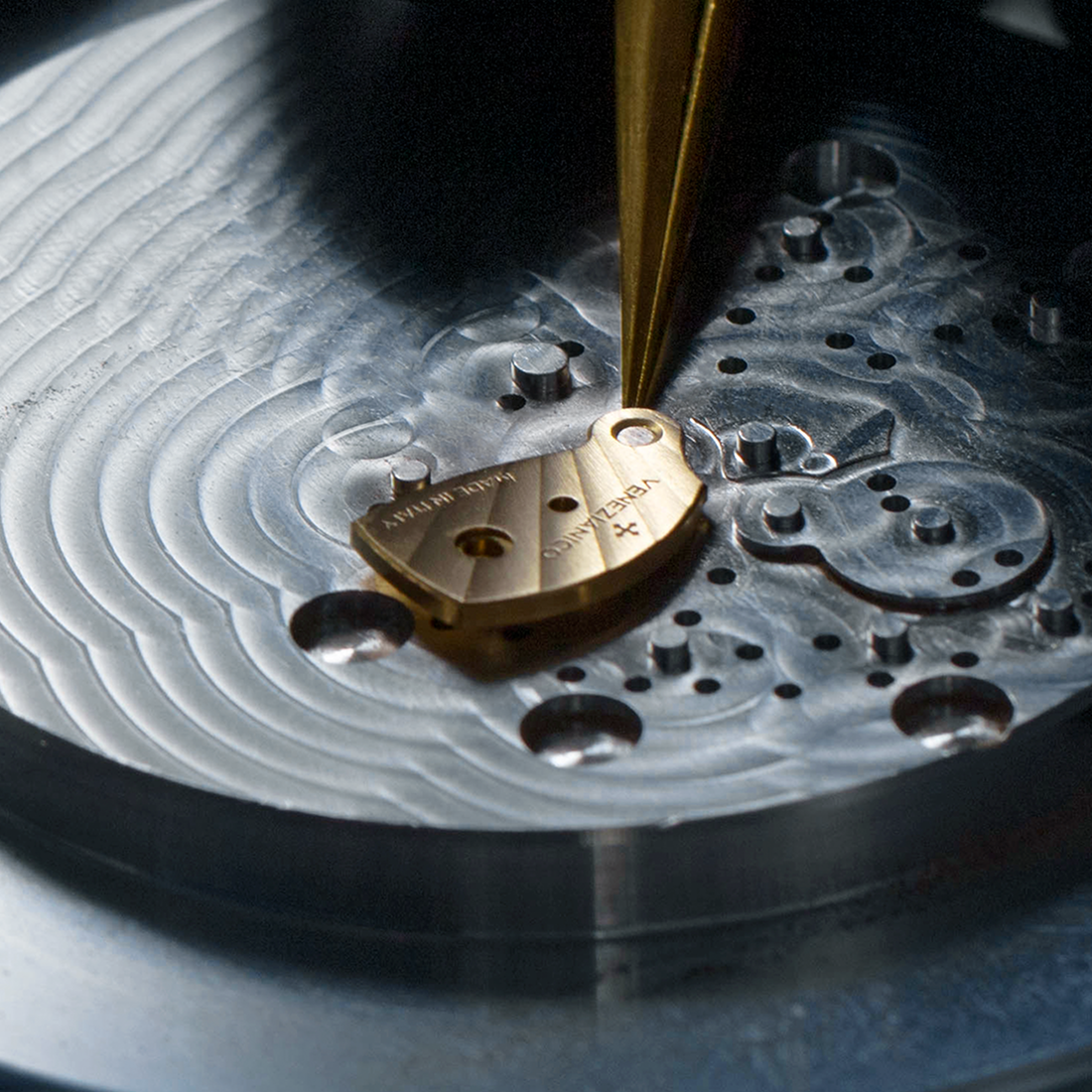

The V5000 is our first proprietary mechanical movement, designed and manufactured in Italy. It offers a 60-hour power reserve within a remarkably slim 3.5 mm profile, and an accuracy of ±3 seconds per day. It features a variable-inertia balance wheel made of copper-beryllium with four masselottes, a dual-anchored balance bridge, KIF Elastor shock protection system, and anti-loosening screws. Every detail is finished by hand with artisanal care, including radial Côtes de Genève, polished anglage, and micro-perlage.

25,200 vibrations/hour (3.5 Hz)

60 hours

Free-sprung with 4 masselottes, made of copper-beryllium by Atokalpa

KIF Elastor®

±3 seconds per day

3.5mm

19

Radial Côtes de Genève, mirror-polished anglage, hand-applied micro-perlage

Bridges machined from solid and treated with chemical nickel

Made in Italy from proprietary design (n. 402025000000420), manufactured by OISA

The Expertise of Berizzi, Technical Director at OISA

Crafted by Atokalpa from a copper-beryllium alloy, this balance wheel is regulated using four masselottes — small peripheral weights that allow the inertia to be adjusted without changing the active length of the hairspring. Compared to traditional balance wheels with a regulator index, the variable inertia system enables more precise and stable regulation over time, minimizing the impact of shocks or positional changes on the watch’s accuracy. This type of balance wheel is typical of haute horlogerie, where long-term chronometric performance is a top priority.

In this system, the transmission of motion is divided into two separate branches: one dedicated to the seconds, the other to hours and minutes. This mechanical separation reduces interference between the gear trains, preventing the continuous motion of the seconds hand from affecting the consistency of the main timekeeping system. The result is greater running stability and more reliable long-term accuracy. A refined approach to movement construction, designed with precision as its highest priority.

KIF Parechoc is a Swiss company specializing in shock protection systems for mechanical movements. In V5000 caliber, we use the KIF Elastor, designed to safeguard the balance against sudden impacts. A star-shaped helical spring, placed around the jewel setting, absorbs the shock’s energy and get back the balance wheel to its optimal position. This compact system offers greater precision and stability compared to simpler alternatives, enhancing the movement’s durability even under dynamic conditions.

Carefully engineered to balance efficiency and practicality, the V5000 is featured by a 60-hours power reserve — well above the average for mechanical movements. This relevant interval allows the watch to maintain stable and accurate timekeeping even after several days of rest, eliminating the need for unnecessary adjustments or winding. It’s a power reserve designed to naturally adapt to different wearing habits, whether used daily or rotated with other timepieces, always ensuring readiness and consistent performance.

Crafted by Atokalpa from a copper-beryllium alloy, this balance wheel is regulated using four masselottes — small peripheral weights that allow the inertia to be adjusted without changing the active length of the hairspring. Compared to traditional balance wheels with a regulator index, the variable inertia system enables more precise and stable regulation over time, minimizing the impact of shocks or positional changes on the watch’s accuracy. This type of balance wheel is typical of haute horlogerie, where long-term chronometric performance is a top priority.

In this system, the transmission of motion is divided into two separate branches: one dedicated to the seconds, the other to hours and minutes. This mechanical separation reduces interference between the gear trains, preventing the continuous motion of the seconds hand from affecting the consistency of the main timekeeping system. The result is greater running stability and more reliable long-term accuracy. A refined approach to movement construction, designed with precision as its highest priority.

KIF Parechoc is a Swiss company specializing in shock protection systems for mechanical movements. In V5000 caliber, we use the KIF Elastor, designed to safeguard the balance against sudden impacts. A star-shaped helical spring, placed around the jewel setting, absorbs the shock’s energy and get back the balance wheel to its optimal position. This compact system offers greater precision and stability compared to simpler alternatives, enhancing the movement’s durability even under dynamic conditions.

Carefully engineered to balance efficiency and practicality, the V5000 is featured by a 60-hours power reserve — well above the average for mechanical movements. This relevant interval allows the watch to maintain stable and accurate timekeeping even after several days of rest, eliminating the need for unnecessary adjustments or winding. It’s a power reserve designed to naturally adapt to different wearing habits, whether used daily or rotated with other timepieces, always ensuring readiness and consistent performance.

The First Model with the V5000

Redentore Utopia is the first model to feature our proprietary V5000 caliber, entirely designed and manufactured in Italy. A timepiece that combines essential design, refined artisanal craftsmanship, and a new vision for Italian mechanical watchmaking. A true turning point in our journey.

Discover more