Nereide Ti-Damascus Limited Edition

Nereide Ti-Damascus is born from the fusion of damascening artistry and material experimentation. The dial is crafted from a combination of titanium alloys, fused and folded using a technique inspired by traditional metalworking, then heat-treated to reveal unique, unrepeatable patterns and textures. The 316L stainless steel case is paired with a polished tungsten bezel, chosen for its durability and visual harmony. Inside beats the Sellita SW200-1 movement, enhanced by an in-house skeletonized rotor featuring radial Côtes de Genève and a purple IP treatment.

CASE MATERIAL: 316L Stainless Steel

DIAL: Ti-Damascus

DIMENSIONS: Ø42mm, lug to lug 49mm

MOVEMENT: Automatic Cal. Sellita SW200-1 Swiss Made

CRYSTAL: Sapphire Glass with anti-reflective coating

LUMINOUS MATERIAL: BGW9 Super-LumiNova®

BEZEL: Tungsten insert, 120 clicks

CROWN: Screw-Down

WR: 20ATM (= 200mt)

BRACELET: Sansovino

All orders include free shipping. Here are the average delivery times:

- EU Countries: 1-2 business days

- United Kingdom: 2-3 business days

- USA: 2-3 business days

- Other Countries: 2-5 business days

If the watch does not meet expectations, it can be returned within 14 days for a full refund of the purchase amount. For more info, check out our Terms and Conditions.

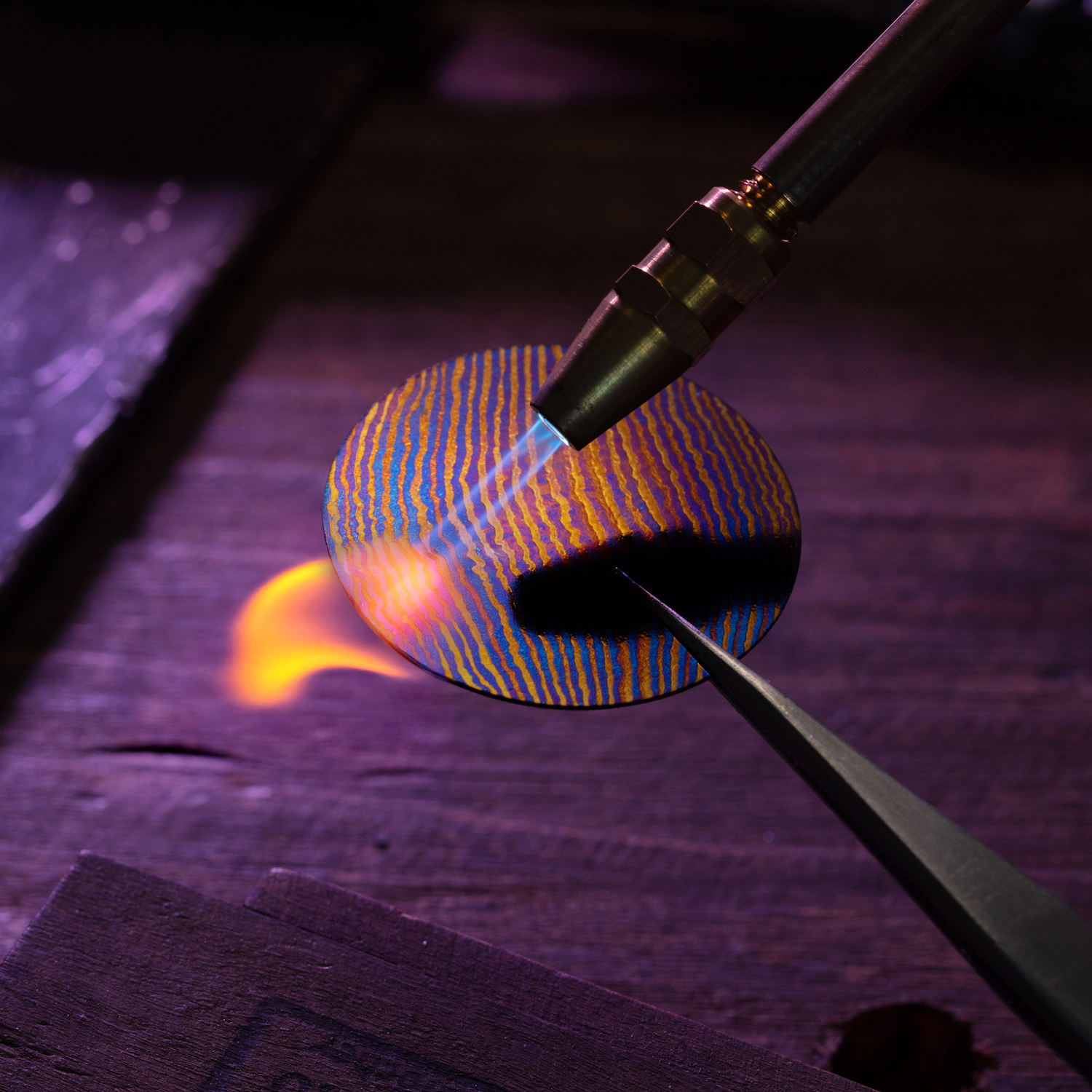

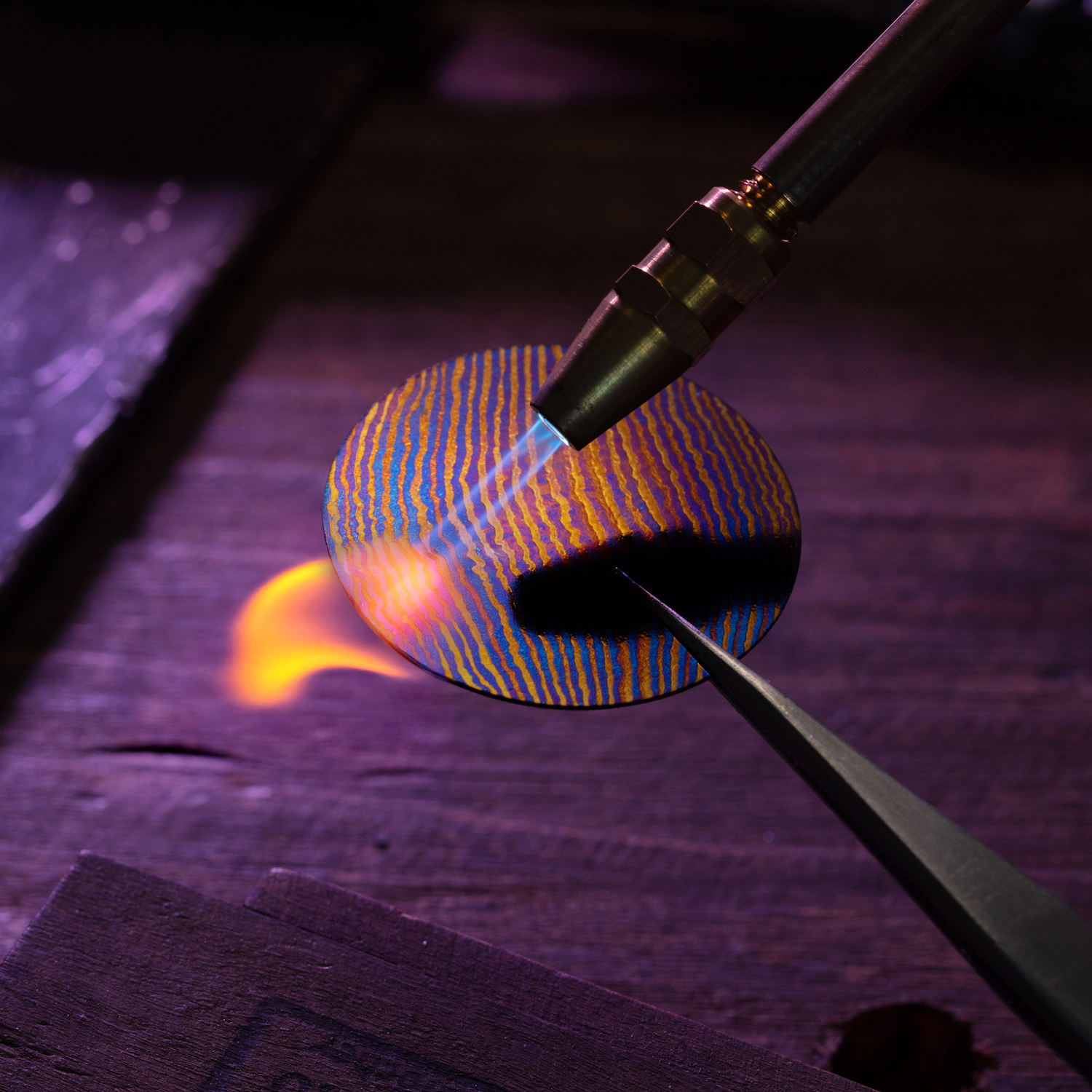

After forging and finishing, the dial is hand-heated with a controlled flame, precisely applied to the surface. The heat triggers a superficial oxidation that does not alter the structure of the metal but permanently transforms its color appearance. The alloys that make up damascus titanium react differently to temperature, generating iridescent shades that develop without pigments, in tones ranging from blue to copper, including gold and purple. Each dial is the result of a unique process, impossible to replicate on a large scale.

For centuries, master armorers of the Mediterranean fused and folded different metals to create strong and decorated blades. This technique, passed down over time and rediscovered in a modern form, re-emerges today in damascus titanium: a titanium alloy with contemporary properties, yet crafted using methods that require patience, precision, and expert hands. Each dial is the result of a manual, slow, and mindful process that leaves authentic and unrepeatable marks on the surface.

The dial is made of damascus titanium, a blend of different titanium alloys combined through lamination, high-temperature welding in a protected atmosphere, and meticulous manual processing. After forging, the surface is shaped, polished, and heat-treated to reveal distinctive patterns and reflections. The vibrant shades emerge from controlled oxidation and vary based on the alloy composition and the angle of the light.

After forging and finishing, the dial is hand-heated with a controlled flame, precisely applied to the surface. The heat triggers a superficial oxidation that does not alter the structure of the metal but permanently transforms its color appearance. The alloys that make up damascus titanium react differently to temperature, generating iridescent shades that develop without pigments, in tones ranging from blue to copper, including gold and purple. Each dial is the result of a unique process, impossible to replicate on a large scale.

For centuries, master armorers of the Mediterranean fused and folded different metals to create strong and decorated blades. This technique, passed down over time and rediscovered in a modern form, re-emerges today in damascus titanium: a titanium alloy with contemporary properties, yet crafted using methods that require patience, precision, and expert hands. Each dial is the result of a manual, slow, and mindful process that leaves authentic and unrepeatable marks on the surface.

The dial is made of damascus titanium, a blend of different titanium alloys combined through lamination, high-temperature welding in a protected atmosphere, and meticulous manual processing. After forging, the surface is shaped, polished, and heat-treated to reveal distinctive patterns and reflections. The vibrant shades emerge from controlled oxidation and vary based on the alloy composition and the angle of the light.

Technical details

Our dive watch, water-resistant to a depth of 200 meters, takes its name from the Nereide submarine, a marvel of Venetian naval technology. This timepiece is engineered to endure strong stresses, making it particularly well-suited for water sports enthusiasts.

Ø42 mm, lug-to-lug 49 mm, total thickness 12.5 mm

Swiss Made Sellita SW200-1 Automatic, 3 Hands with Date Function

316L Stainless Steel

Tungsten, Polished and Scratch-Resistant with a Hardness of 9/10 on the Mohs Scale

Damascus titanium, Precision-Cut 0.4mm Layer on brass base

Sapphire with anti-reflective coating

Swiss-Made BGW9 Super-LumiNova®

20 Atmospheres (200m/656ft)

A component designed to remain visible

The Nereide Ti-Damascus is equipped with the Sellita SW200-1 caliber, chosen for its precision and reliability. What makes it unique is the skeletonized rotor developed in-house: a technical yet expressive element, decorated with radial Côtes de Genève and finished with anglage on the openings. The workmanship enhances the brilliance of the components and reveals glimpses of the movement in action. The purple IP treatment applied to the oscillating weight echoes the iridescent tones of the dial, creating a chromatic coherence that connects the front and back of the watch in a unified design vision.

500 pieces Limited Edition

For this edition, we created dedicated packaging designed to reflect the visual identity of the model in a coherent and recognizable way. The box’s graphic design is an abstract interpretation based on the colors and variations that damascus titanium takes on during the heat treatment: unpredictable shades, iridescent patterns, sharp contrasts that naturally emerge from the metal. The goal was not simply to decorate, but to create a visual extension of the dial — an element that accompanies the watch and shares the same chromatic language.